The Unfortunate

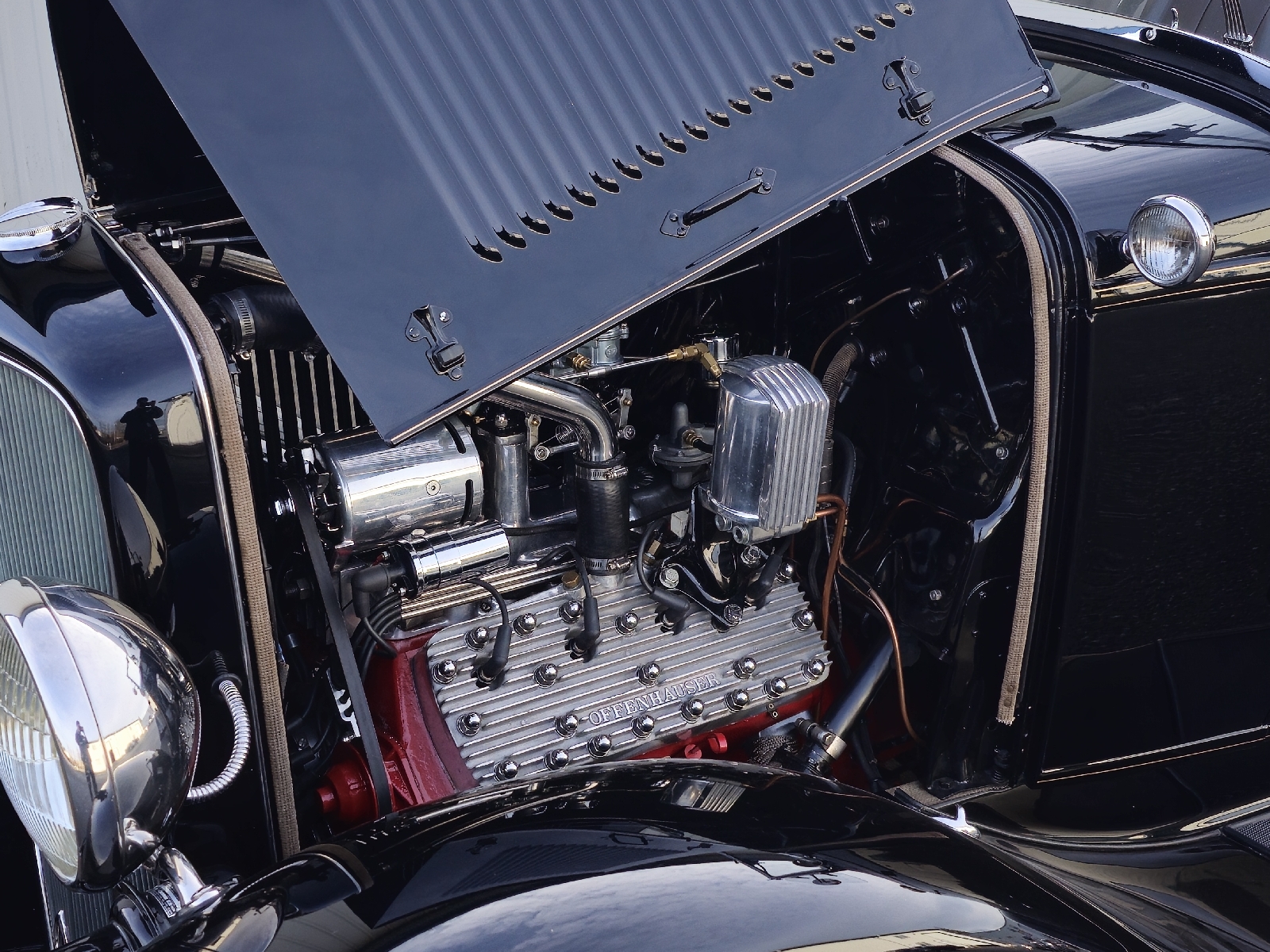

This beautiful 1932 Ford Model B came into the shop with the initial concern of a coolant leak, little did we know that it would turn into a much larger project.

The car was done from top to bottom as a period correct hot rod consisting of a 1948 Mercury Flathead V8, 1940 Ford Brakes, and some shiny parts to make it faster.

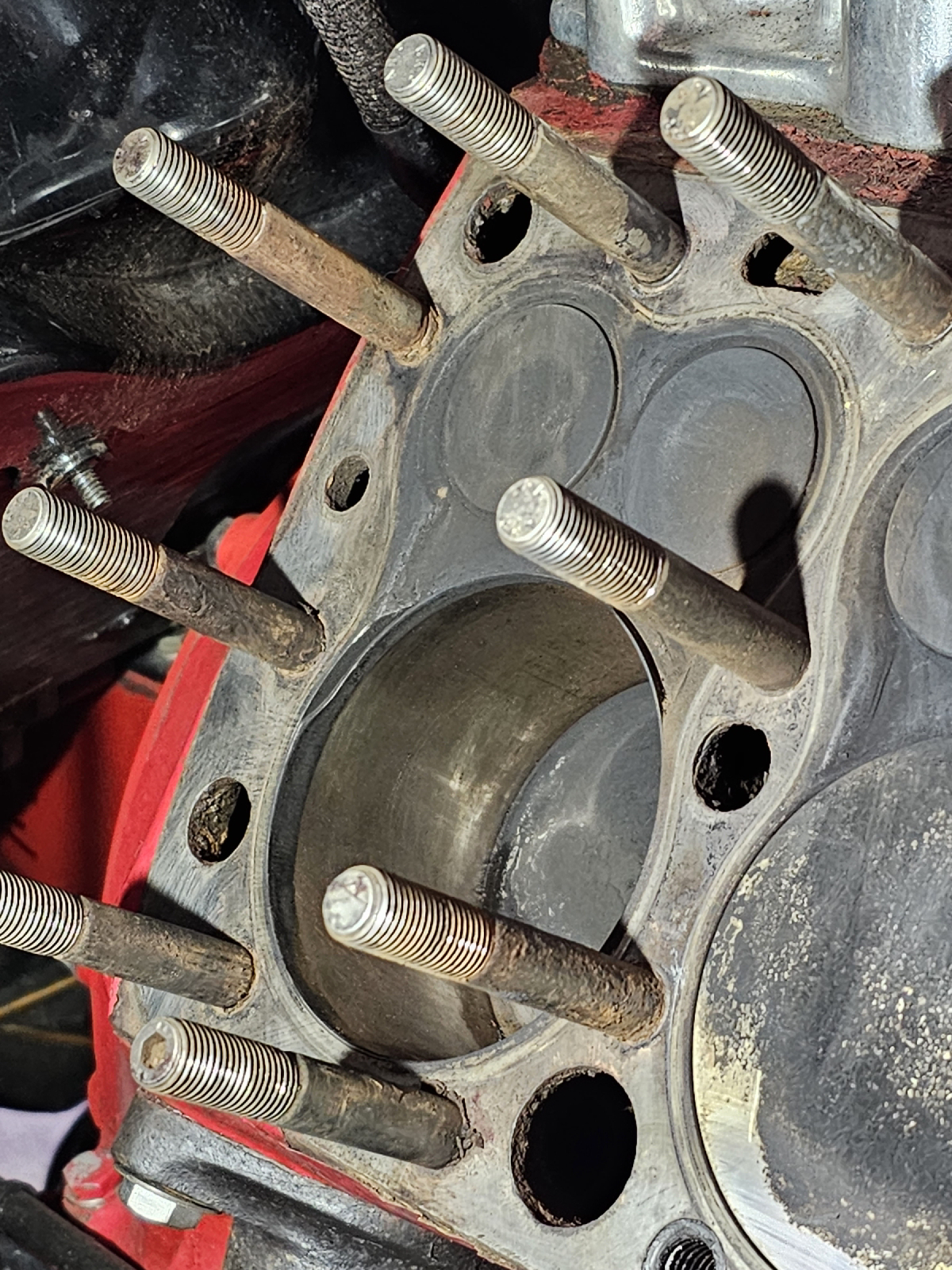

Now the coolant leak was coming from the passenger side front of the head gasket, not a big problem. We pull the head and as we are inspecting the block and pistons while we have it apart, we notice that the motor had a spun cylinder sleeve and that the cylinder sleeves were exceptionally thin. Now while normally re-sleeving a motor isn't a big deal, but we are dealing with a motor from the 40's.

While looking for parts, we realized pretty quickly that we could not find a sleeve that would fit the current bore and piston size that we have in the car. Now this isn't necessarily the most surprising thing due to the motor being almost 80 years old.

For those unfamiliar with motors, a cylinder sleeve is an important part to ensure there is no wear on the cylinder block and to achieve the desired cylinder bore diameter.

After we discovered this problem, the customer wanted us to pull the other head to make sure that no other sleeves had spun.

Now the problem with not being able to find parts that fit, is that we would have to re-sleeve the entire motor and get pistons to match. A much larger job than originally anticipated. So we pulled the hoods, the radiator, and the motor to strip it down and send it out for machining.

Now flathead motors are not so common anymore, in fact ford made the last one in 1953, so here's a quick description on how they work.

A normal motor has valves, cams, and lifters in the head itself; Flathead motors have everything contained in the block and the heads act more as a lid for cooling and compression. This all means that it is much easier to remove the heads because you do not need to touch timing at all when removing the head, very similar to the more modern pushrod motors.

Continue onto the next post to read about the rebuild process when we got it back from the machine shop!

Comments

Post a Comment